Ever since I got my 16 harness Ashford table loom I have been doing a lot of mining my weaving library for drafts of over 8 harnesses. Most of my books are of the 4 to 8 harness persuasion, although I have a few books that go into the 8-32 harness stratosphere. Most of my books I’ve had for decades. I have Weaves A Design Handbook by Eleanor Best (1987). I have 8/12…20 An Introduction to Multishaft Weaving by Kathryn Wertenberger and the two-volume collection of patterns by Jakob Angstadt. I also have the newer books by Marian Stubenitsky.

Those books are fine, but probably the most precious part of my library is my collection of Weaver’s Magazines. There were 44 issues published, and I have all but the first four. Whenever I sift through my stack, I always see new stuff, and this time I was struck by all the 16 harness projects that were included, and was just so grateful that I have kept these magazines for all this time.

In particular, I found three magazines with articles on Turned Taqueté projects. The above issue #42 Winter 1998 has an article by Alice Schlein for a project for a 16 harness reversible rug with an advancing twill threading and a one-shuttle Turned Taqueté liftplan (treadling). And what is the pattern? Circles!!

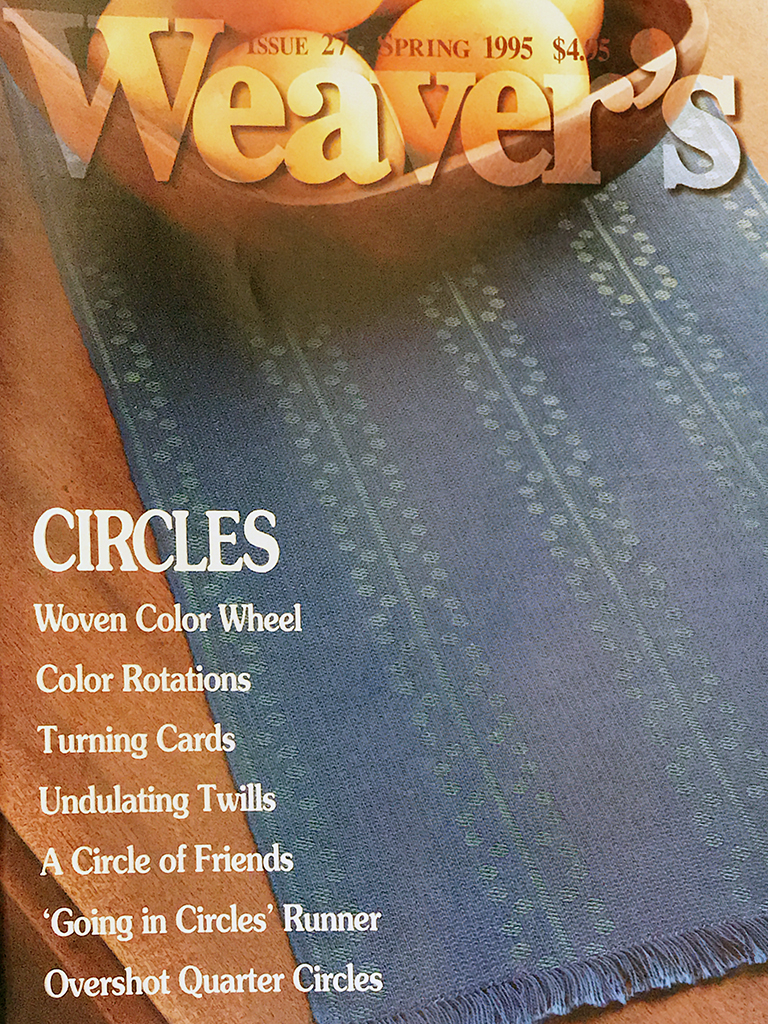

The next issue 27 Spring 1995 has an article by Lucille Crighton which shows how to use Turned Taqueté with three different threading sequences on 16 harnesses for some really creative patterns using different textured yarns.

This issue #12 Winter Quarter 1991 has an article by Betsy Blumenthal titled “One-Shuttle Wonderful” and it was a revelation. It is a thorough explanation of straight draw Turned Taqueté from 4 harnesses to 16 harnesses. (She did leave out 8 harnesses, but I’ve got that covered. Read on!)

Blumenthal starts out on four harnesses on a straight draw, very much like my first forays into Turned Taqueté. Two pattern blocks are possible by changing color order from A=DLDL to B=LDLD. She then zooms up to 16 harnesses, on which four pattern blocks are possible on a straight draw threading, with no color order changes. A=DLDL(harnesses 1234), B=DLDL (harnesses 5678), C=DLDL (harnesses 9,10,11,12), and D=DLDL (harnesses 13,14,15,16). As in standard block weaves, any 4-block profile draft may be used here, and woven with one shuttle. Tie-ups provide for combinations of all dark on top, all light on top, plus each block separately or in combinations on top. I was doing a happy dance.

But what about 8 harnesses? I scaled back and came up with a 2-block threading and tie-up that provided for all dark sections, all light sections, and sections with light and dark, or dark and light.

I’m already planning out new ideas for towels. So. Much. Fun.